Cradle-to-cradle

We haven’t just been living sustainability since yesterday, but have had it embedded in our DNA since our founding in 1977.

We operate a genuine recycling economy with PE plastic residues from pipe production.

Instead of disposing of them, we use them to produce very durable lawn edging profiles. Due to its excellent raw material quality, it is very UV-resistant and resistant to frost.

We haven’t just been living sustainability since yesterday, but have had it embedded in our DNA since our founding in 1977.

Coal, natural gas and cellulose are other raw materials for plastics production.

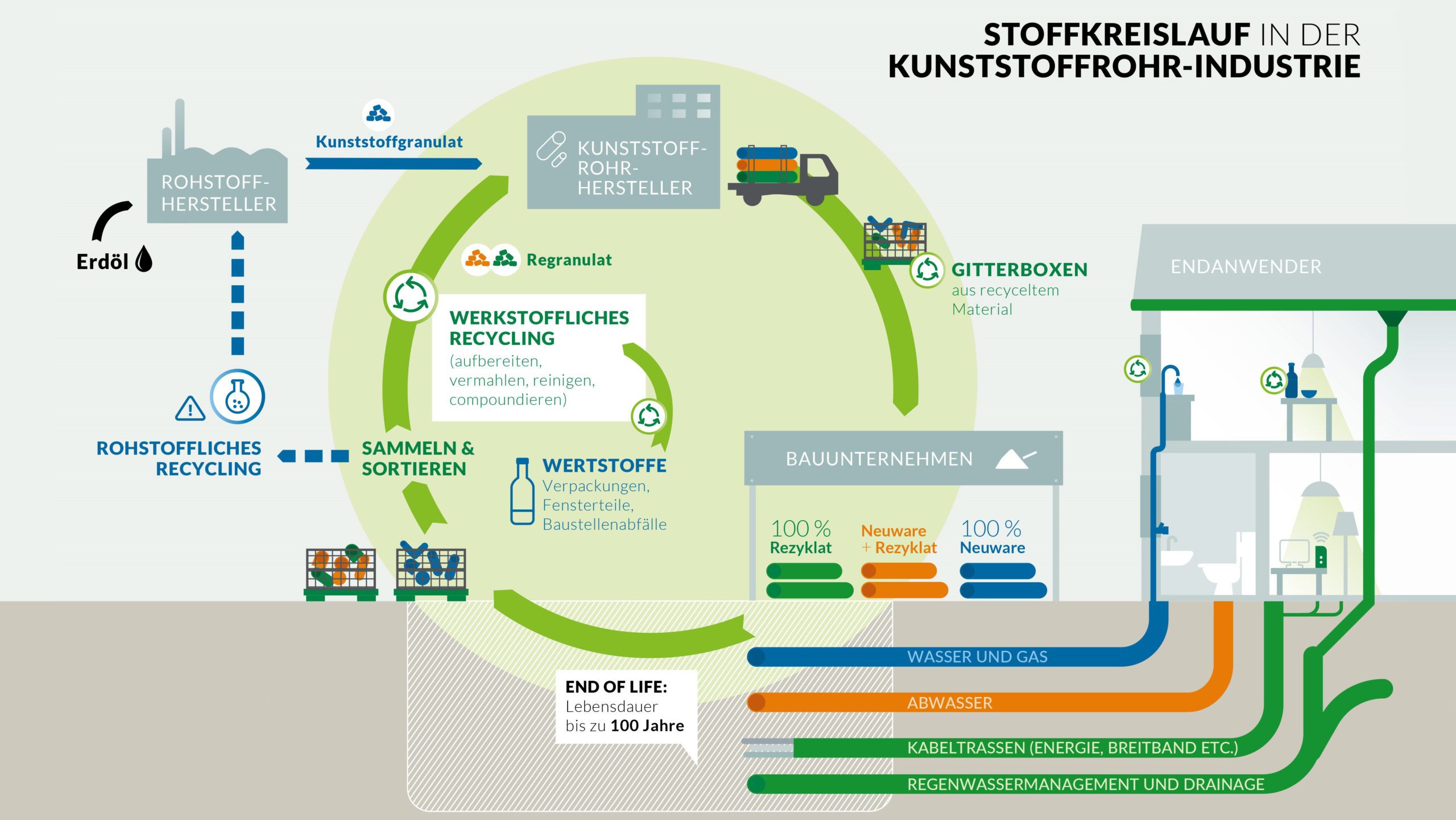

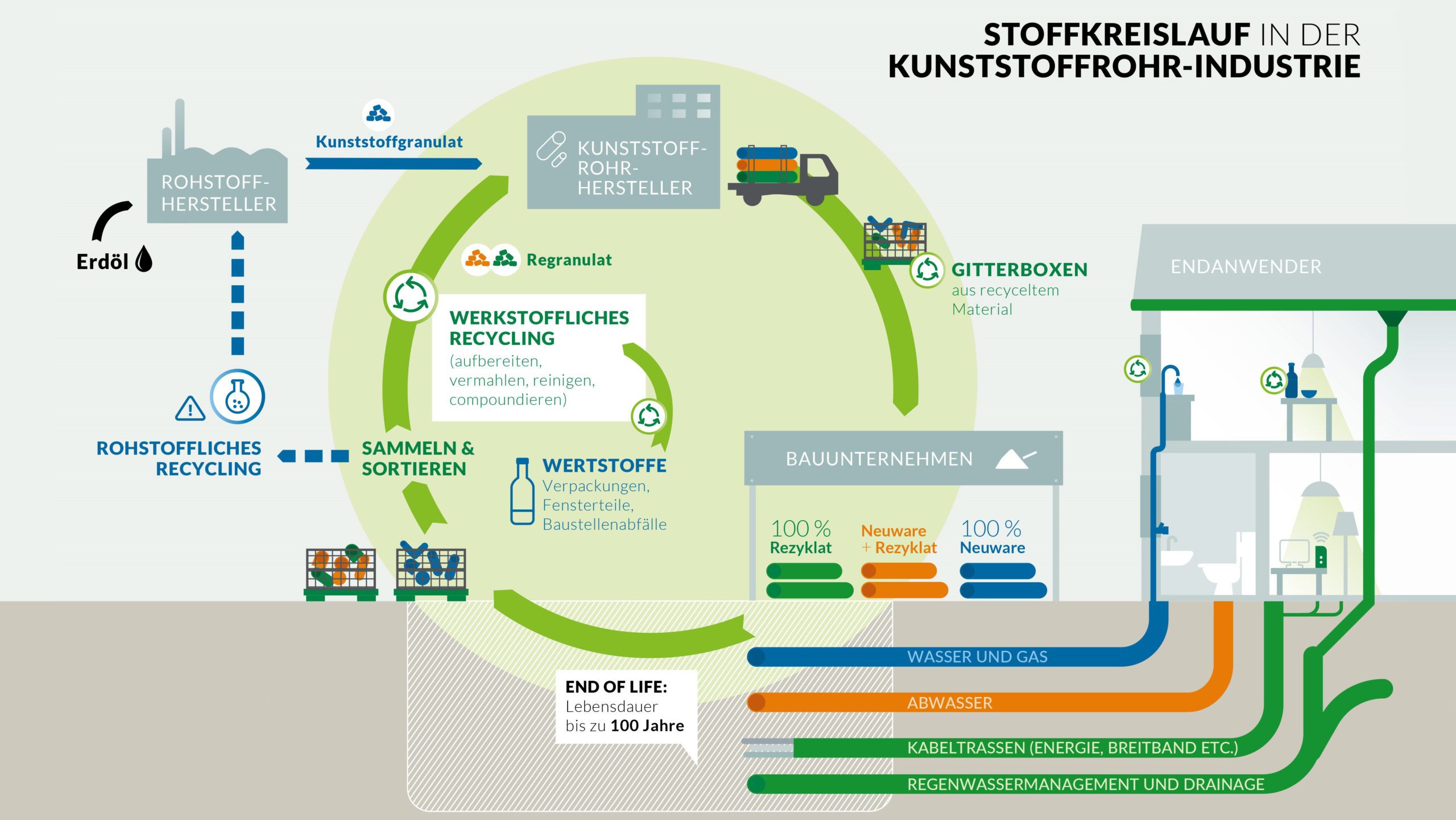

The finite nature of resources demands that they be used sparingly and that maximum recycling be ensured. That is why the plastic pipe industry has been gradually building up a functioning recycling infrastructure since the mid-1990s.

In addition to old pipes and processing residues, construction site waste, window profiles, packaging and plastic screw caps are also recycled. The collected waste is sorted, cleaned and ground into grist. A fundamental distinction must be made between mechanical and feedstock recycling:

In material recycling, regrind is produced from the used plastics and processed into secondary pipe materials, which in turn are used to make new pipes.

In raw material processing, the plastic products are returned to their chemical starting materials and these are used for the production of new plastics. By nature, the ground material is a mixture. Although the fractions can be separated according to plastic types such as polyethylene, polypropylene or PVC, the mixture is not completely homogeneous with regard to the specific formulations and production batches of the raw material producers.

Incidentally, the recycling process is not without effort. This can lead (especially if oil prices are moderate) to the price level of reprocessed old goods coming close to that of new goods. Nevertheless, the demand for recyclates is persistently high – often the available supply is not sufficient to meet it.

In parallel to recycling, the plastic pipe industry started in the mid-1990s to develop and introduce a deposit-based packaging and transport system for the supply of pipes and fittings to its customers. After Euro wooden pallets were used in the beginning, this system is now based on plastic pallets made exclusively from recycled materials.

We are certified according to